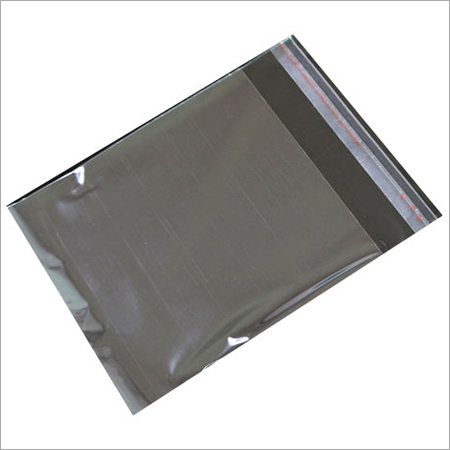

Antistatic Bags

Price 2 INR/ Piece

Antistatic Bags Specification

- GSM

- 50-120 GSM

- Product Type

- Antistatic Bags

- Material

- Polyethylene (PE), Polypropylene (PP), PET / Metallized polyester

- Size

- Standard & customized sizes (3x5, 4x6, 6x8 inches, etc.)

- Color

- Pink, Silver, Transparent, Blue, Custom available

- Design

- Plain, Metallized, Printed Logo on Request

- Feature

- Anti-static, Moisture proof, Dust resistant, Durable, ESD protection

- Sealing and Handle

- Heat sealable, Zip lock, Open-top

- Customized

- Yes, possible

- Use

- Electronic component packaging, Protective packaging

- Surface Handling

- Smooth, Antistatic Coating

- Capacity

- Varies as per size; typically 0.5 kg 5 kg

- Printing Options

- Custom printing (ESD warning symbol, barcode, logo, instructions)

- Thickness

- 0.05 mm 0.20 mm (customizable)

- RoHS Compliance

- Yes

- Closure Type

- Resealable, Heat seal

- Static Discharge Protection

- Surface Resistance: 10^6 10^11 ohms/sq

- Temperature Resistance

- -20C to +80C

- Shelf Life

- 12-24 months under standard storage

- Transparency

- Available in transparent and semi-transparent variants

- Application

- Packaging of PCBs, ICs, resistors, sensors, microchips, mobile parts

Antistatic Bags Trade Information

- Minimum Order Quantity

- 1000 pieces Pieces

- Supply Ability

- 20000 Pieces Per Week

- Delivery Time

- 2-5 Days

About Antistatic Bags

Comprehensive ESD Protection for Electronics

Our antistatic bags provide robust electrostatic discharge protection, featuring surface resistance between 10^6 and 10^11 ohms/sq. This safeguards your sensitive electronic components from static-related damage during storage and transit. The bags are available in various sizes, thicknesses, and closure types, catering to the diverse needs of manufacturers and exporters.

Versatile Design and Customization

Choose from a selection of materials, colors, and finishes to suit specific applications. The bags can be transparent, semi-transparent, plain, metallized, or customized with logos and handling instructions. Available in sizes ranging from 3x5 to 6x8 inches or tailored to specification, their moisture-proof, dust-resistant, and durable construction ensures long-term reliability.

Ease of Use and Compliance

Designed for convenience, these bags feature options like resealable closures, heat sealable seams, and smooth surfaces. They fully comply with RoHS directives and offer a shelf life of up to 24 months under standard storage. Custom printing with ESD warning symbols, barcodes, or branding is available for added safety and identification.

FAQs of Antistatic Bags:

Q: How do antistatic bags protect electronic components from static discharge?

A: Antistatic bags feature surface resistance levels between 10^6 and 10^11 ohms/sq, which dissipate static electricity safely. This protects sensitive electronic items such as PCBs and microchips from electrostatic discharge (ESD), reducing the risk of component failure during handling and transportation.Q: What are the available customization options for these antistatic bags?

A: You can customize bag thickness (0.05 mm 0.20 mm), material (PE, PP, PET/metallized polyester), closure type (resealable, heat seal, zip lock, open-top), color (pink, silver, blue, transparent), size, and printing (logos, barcodes, ESD warnings, or instructions) to match your specific requirements.Q: When should I choose metallized versus transparent antistatic bags?

A: Metallized bags provide enhanced ESD protection and shielding properties, ideal for highly sensitive components, while transparent or semi-transparent bags are best when easy visual inspection of contents is needed, suitable for less sensitive parts.Q: Where are these antistatic bags commonly used?

A: These bags are widely used in electronics manufacturing, assembly, and export industries for packaging printed circuit boards, integrated circuits, sensors, resistors, and mobile device components, both within India and for international shipment.Q: What is the typical process for sealing and handling these bags?

A: Depending on the chosen closure type, you can seal the bags using heat sealing equipment, by pressing a zip lock mechanism, or by simply folding open-top variants. Smooth surfaces and antistatic coatings make them easy to handle during both manual and automated packaging operations.Q: What benefit does RoHS compliance provide for these bags?

A: RoHS compliance ensures that the bags do not contain hazardous substances, making them safe for use in various industries and suitable for export to countries with strict environmental regulations.Q: How long can these bags safely store electronic components?

A: With proper storage in standard conditions, antistatic bags maintain their protective properties and integrity for 12 to 24 months, ensuring reliable long-term storage of electronic parts.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Self Adhesive Bags Category

Poly Adhesive Bag

Price 2 INR / Piece

Price Or Price Range 0.50 - 3.00 per piece / Piece

Minimum Order Quantity : 5000 Pieces Pieces

Design : Plain, No Printing

Material : Other, Polyethylene (PE)

Size : Customized; available in various sizes

Self Adhesive Polypropylene Security Bags

Price 2 INR / Piece

Price Or Price Range 2 - 10 per bag depending on size & order quantity / Piece

Minimum Order Quantity : 1000 Pieces Pieces

Design : Plain with optional custom print

Material : Other, Polypropylene

Size : Standard and custom sizes available (e.g., 8x10 inch, 10x12 inch, etc.)

Adhesive Printed Plastic Courier Bag

Price 2 INR / Piece

Price Or Price Range INR 1.5 - 4.5 per piece / Piece

Minimum Order Quantity : 500 Pieces Pieces

Design : Adhesive printed with customizable branding/logo

Material : Other, LDPE / Polyethylene

Size : Multiple sizes available (Standard: 12 x 16 Inch, 10 x 14 Inch, 14 x 19 Inch, etc.)

Self Adhesive Bags

Price 2 INR / Piece

Price Or Price Range Rs. 120 - Rs. 180 per Kg / Piece

Minimum Order Quantity : 5000 Pieces Pieces

Design : Plain, Optional Printing

Material : Other, Polypropylene (PP) / Lowdensity Polyethylene (LDPE)

Size : Customizable

Factory Address:

396 & 403, Moraiya Village

Sarkhej Bavla Highway,

Taluka Sanand, Ahmedabad-382213

Telephone: Factory +91 2717656552

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese